Flexible Shop Floor Problems are extensions of classical Shop Floor layouts as the Flow-shop or the Job-shop problems. The word "flexible" refers to the design of the production line, where several machines can perform the same operation.

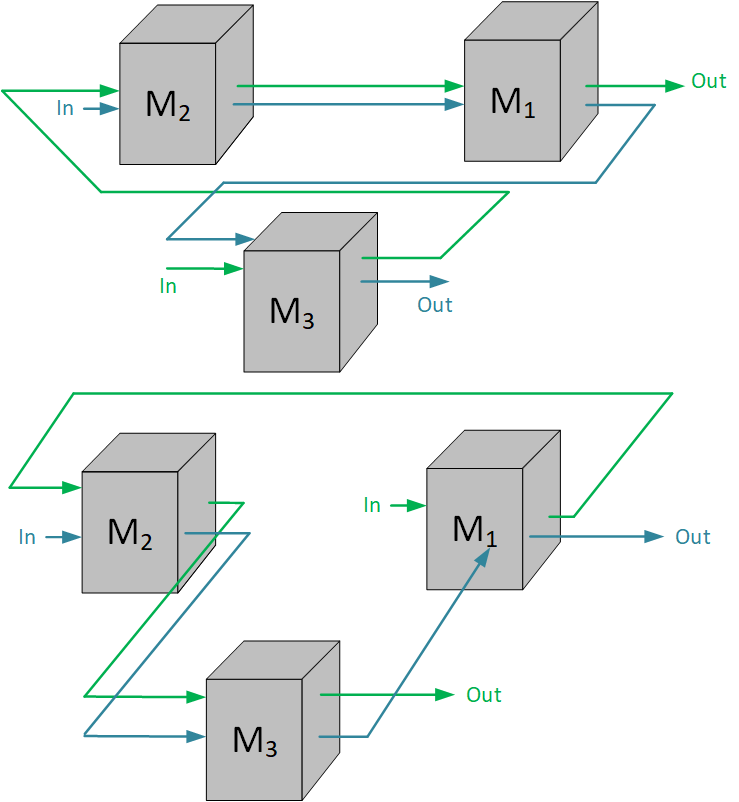

For instance, the Flexible Job-shop Problem (FJSSP) is an extension of the classical Job-shop problem. This problem has been introduced by Brucker and Schlie in 1990, and called at the moment "Job-Shop Scheduling with Multi-Purpose Machines - renamed Flexible Job-shop later. In this extension, operations can be processed on several machines whereas only one machine is available for each operation in the classical Job-shop. Several types of Flexible Job-shop exist, ranging from the one considering some operations with few available machines, to completely flexible systems where all operations can be assigned to any machine. The figure below shows such a shop floor where products follow different routes in the system.

The advantage of this problem is to better stick to reality, where it is common to have multi-purpose machines. The idea is to benefit from the machine diversity in the shop floor. Actually, by assigning an operation to a particular machine it is possible to finish the operation faster than assigning it to the old and slow machine. However, if several operations are to be scheduled, it could be still interesting to use the old machine for a specific operation, and schedule the other ones on the fast, recent (and energy efficient - this will be a topic in a future post) machine. By solving the two problems (assignment and scheduling) it is possible to increase the productivity of the shop floor.

Another interesting aspect is the robustness of a Flexible Manufacturing System (FMS). Indeed, every system is subject to failures. In a FMS, the availability of several machines for processing an operation can be a strength as it is possible to reassign an operation to another machine if a breakdown occur, or at least, to reassign the other operations that were supposed to be processed after the current one.

A paper has been published in the EAAI journal (Engineering Applications of Artificial Intelligence) by (Kemmoé, Lamy and Tchernev, 2017), DOI: 10.1016/j.engappai.2017.04.002. An abstract will added sson in the publications' section.